Traditional articles on fuel saving tend to pluck the low-hanging fruit such as removing the roof rack, emptying the boot, and planning your journeys to avoid traffic. Let’s assume you already do all of those things, though, and instead consider where the more marginal gains can be found. To do that, it can be helpful to think of fuel saving in terms of three fundamental categories: Rolling Resistance, Aerodynamic Resistance and Mechanical Resistance.

Rolling Resistance

Rolling resistance is the opposition you feel when you try and push the car. Typically, a one-tonne car on a dry asphalt road will require a force of about 100 Newtons to roll it along. In wet weather, when the tyres are pumping a lot of water out from under the tread, rolling resistance is increased.

Measures you can take to reduce rolling resistance aren't massive, but making sure the tyres are running at the right pressures is important. "Tyre pressures are critical," says Andy Dawson of fuel consumption experts, Dawson Auto Developments. "I run at the manufacturers' high-speed settings as opposed to the comfort settings. It doesn't make a big difference to comfort, but it can make a big difference to the way the car rolls."

Not specifying massively wide wheels can also help, as they have higher rolling resistances and also contribute to aerodynamic drag. You might also consider swapping to a low-rolling resistance tyre, which have higher levels of silica in their compounds and special tread patterns that can typically save up to 15 per cent in rolling resistance compared with a more conventional alternative.

You should also make sure the wheels are properly aligned so they are not fighting against each other, which will increase rolling resistance and cause premature wear.

Aerodynamic Resistance

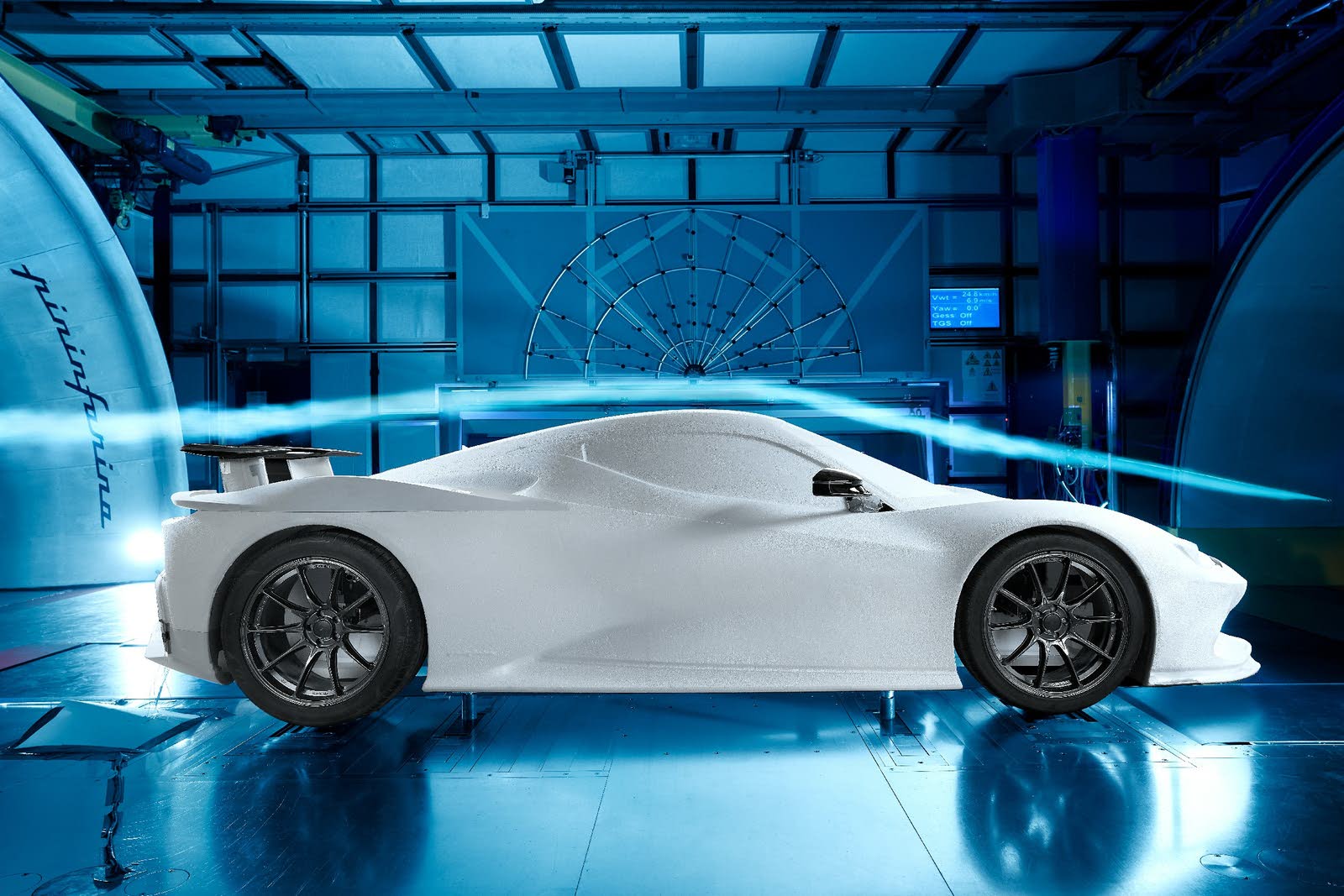

Aerodynamic resistance is the car's drag through the air, which becomes more important the faster you are travelling. Aerodynamic resistance typically overtakes the drag imposed by rolling resistance at about 60mph, although even below that speed it's an important part of how a car is designed. A car's resistance to the air is expressed in its coefficient of drag (Cd); Volkswagen's XL1 of 2014 had a Cd figure of 0.186, the Mercedes-Benz CLA (pictured below) 0.28, and a 1997 Jeep Wrangler 0.58. An upright cyclist has a Cd of about 1.0.

In recent years car designs have started to become a great deal more aerodynamic, with underbody panels and complicated winglets, which help separate the airflow from the body, but even if you’re driving an older car there are certain things you can do to maximise its aerodynamic efficiency. For example, you should close the windows at speeds above 40- to 50mph, when the drag caused by having them open uses more fuel than the air-conditioning system would, and always replace underbody panels if they become detatched.

When thinking about aerodynamic resistance, it helps to have an understanding of the effects of speed on the car. The power required to push an object through the air increases as the cube of the velocity, so if you double the speed, the drag increases by a factor of four. So, slowing down to 65mph instead of 75mph will have a big beneficial effect.

"It's the other big killer of fuel consumption," says Dawson. "If you add in brake, tyre and wheel-bearing drag, it can be higher than a square/cube law, plus you have to accelerate to get there and then brake earlier to slow – just leave a couple of minutes earlier and cruise."

Mechanical Resistance

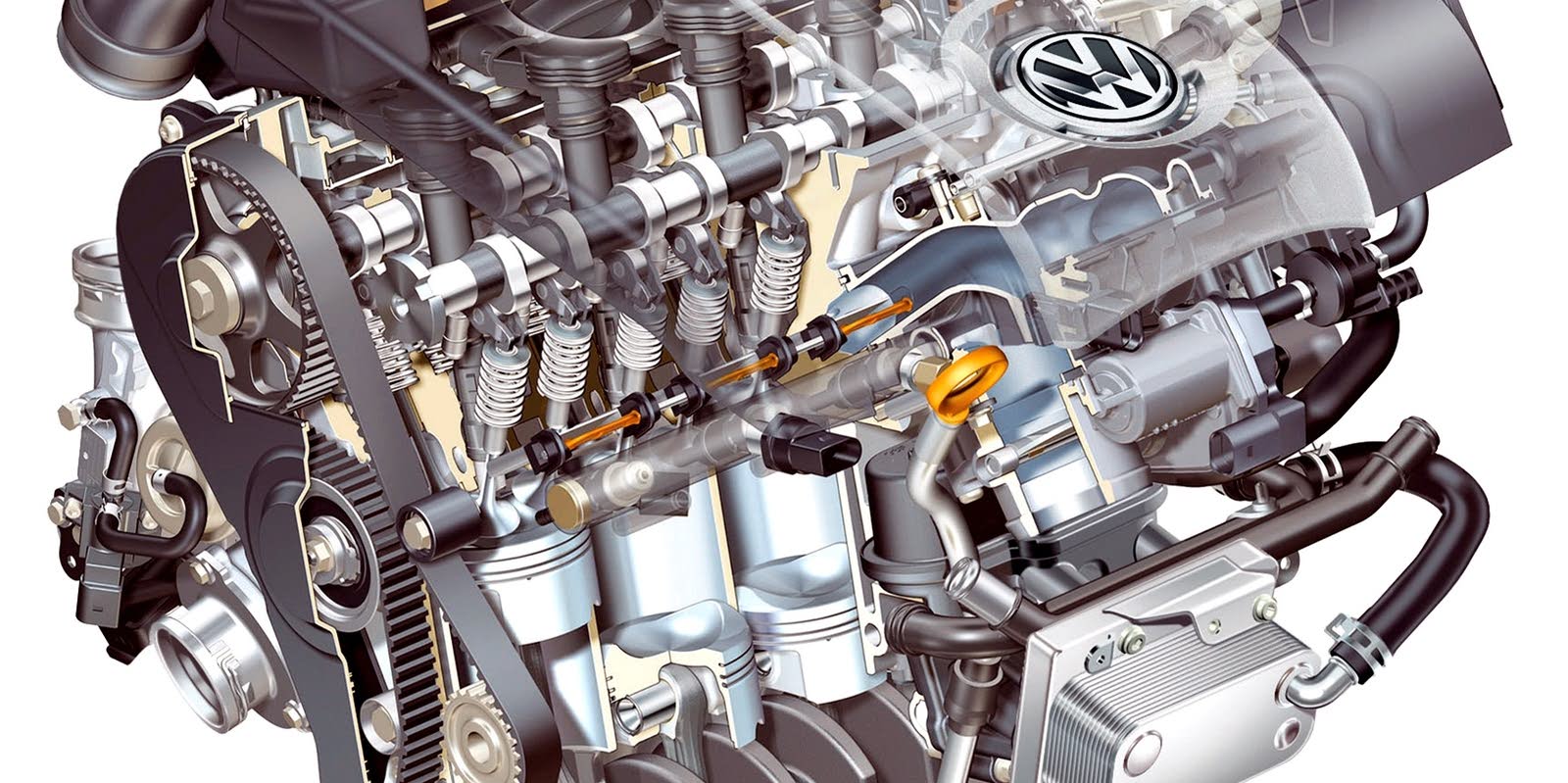

Mechanical resistance is a measure of the drag inside the engine in different operating conditions, and also the friction imposed by the gears meshing and churning oil in the transmission. The last factors can be dealt with by using the right lubricants in axle, engine and gearbox. But dealing with the others is more complicated. Anyone who has had the experience of turning a Ducati desmodromic valve engine by hand will know how much load valve springs put on the engine: and they are not alone.

The inertia of what are called the rotating masses (crankshaft, connecting rods, pistons, camshafts and flywheel) plus driving water and oil pumps and an alternator will oppose movement and impose drag. A combustion engine typically splits the calorific value of its fuel into thirds: one third as useful work, the other two thirds as heat which is lost roughly equally through the exhaust pipe and the radiator.

Of course, in more than 100 years of continuous development, engineers have come up with ingenious ways of either minimising the losses or recovering some engine heat. A turbocharger, for example, helps recover exhaust gas energy to drive more air into the engine. Low-friction coatings and valve-gear design help reduce frictional losses; intelligent water and oil pumps only pump when required; and intelligent alternators do likewise. Cylinder deactivation can reduce the engine's fuel requirements at part-throttle operation, and some of the latest automatic gearboxes will freewheel on light throttle openings, too.

How Hybridisation Helps

Hybridisation of any sort helps recover braking energy as battery charge to either offset the demands of the alternator or actually drive the car. But hybrids also help to minimise pumping losses, which is the effort taken up by forcing the air in past the throttle butterflies and down the inlet tract, compressing it in the combustion chambers and then forcing it out of the exhaust manifold and pipes. The bigger the engine capacity and the higher the engine revolutions, the greater the pumping losses. Or put another way, to minimise pumping losses, you need to keep the engine revs low, change up the gears early, and use a light throttle.

But there's also a specific fuel curve for combustion engines, which is the rate of fuel consumption divided by the power produced. On combustion engines it tends to be a gentle curve sloping upwards at each end of the rev range.

Dr Thomas Zenner from Ford of Europe Powertrain Engineering explains why this is important. "You need to look at the friction in a combustion engine," he says, "which generally has a linear relationship with the speed of the engine; the lower the better. But then there is the thermodynamic efficiency, which is the big one and very low revs will reduce the efficiency of a combustion engine. There is nothing you can do about it."

In other words, you need to keep the revs low, but not too low, or the efficiency drops off. Zenner explains that a full hybrid circumvents this by running the engine at peak efficiency at low roads speeds and diverting excess power into the battery. Dawson bears this out with his most recent economy run in a Ford Fiesta where the car was more economical at 42mph in fifth gear than it was in sixth, for it was here that the engine was working at its most efficient period and the aerodynamic drag was at its lowest.

Don't Be Idle

The last thing to mention is idling; don't do it. You're simply churning the engine against its own resistance, using fuel to no avail, putting avoidable wear into the valvetrain and camshaft profiles, and poisoning the environment. That goes for warming the engine up without the car moving, too.

The good news about all of this complicated stuff is that the car makers are doing the hard work. All you have to do to take advantage of it is moderate your speed, acceleration and braking. As Dawson says: "the biggest killer of fuel economy is the centre pedal, so don’t accelerate and then brake, just cruise and use your brakes as little as possible."